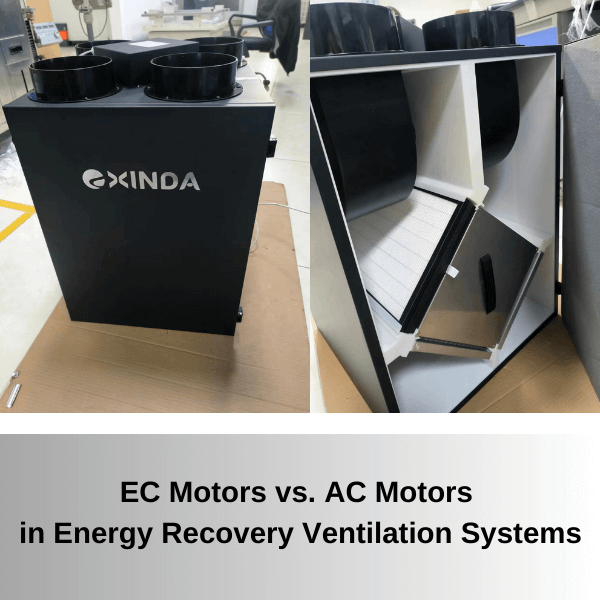

Energy Recovery Ventilator Diagram

As an Energy Recovery Ventilation manufacturer & supplier, Energy recovery ventilation (ERV) systems play a vital role in maintaining indoor air quality while minimizing energy consumption. Within these systems, the choice of motor technology, specifically EC (electronically commutated) motors and AC (alternating current) motors, significantly impacts performance and efficiency. This article aims to provide a comprehensive comparison between EC motors and AC motors in the context of energy recovery ventilation.

Energy Efficiency

EC Motors: EC motors are renowned for their high energy efficiency. They utilize advanced motor control technology, allowing for precise speed control and optimization based on real-time demand. This leads to reduced energy consumption, especially under partial load conditions, resulting in substantial energy savings over time.

AC Motors: While efficient, AC motors are less energy-efficient compared to EC motors. They operate on the principle of alternating current and lack the advanced control mechanisms found in EC motors. Consequently, AC motors may consume more energy, particularly in applications with varying load conditions.

Speed Control and Performance

EC Motors: EC motors excel in speed control and performance due to their advanced electronic control systems. They offer precise speed regulation, allowing for optimal airflow adjustments in energy recovery ventilation systems. EC motors can maintain consistent performance even at low speeds or under varying load conditions, ensuring efficient operation and enhanced indoor air quality.

AC Motors: AC motors provide reliable performance but may not offer the same level of speed control as EC motors. Their speed regulation capabilities are comparatively limited, which can affect the ability to fine-tune airflow in energy recovery ventilation systems. However, AC motors can still provide satisfactory performance in applications that do not require precise speed control.

Installation and Maintenance

EC Motors: EC motors are generally more user-friendly in terms of installation and maintenance. They are compact, lightweight, and easy to integrate into existing systems. Additionally, many EC motors come with built-in diagnostics and communication capabilities, simplifying monitoring and troubleshooting processes.

AC Motors: AC motors are widely used and familiar to technicians, making installation and maintenance straightforward. However, their design, which includes brushes and commutators, may require more frequent maintenance to ensure optimal performance.

Both EC motors and AC motors have their strengths and applications in energy recovery ventilation systems. EC motors excel in terms of energy efficiency, precise speed control, and enhanced reliability. Conversely, AC motors offer cost-effectiveness and simplicity. When selecting the motor type for an ERV system, factors such as energy efficiency requirements, precise speed control needs, and specific applications should be considered.

About Exinda

Exinda, a leading manufacturer in the heat pump industry, offers a complete supply chain and specializes in various air source heat pump units for residential & commercial,heating & cooling use, as well as HRV & ERV ventilation systems. With OEM/ODM services and a focus on energy-saving solutions, Exinda incorporates advanced technologies such as variable frequency and environmentally friendly refrigerants.

With the 60,000m² factory, efficient production and delivery are ensured, supported by a dedicated service team. Committed to corporate social responsibility, Exinda actively pursues opportunities for greener energy solutions.

Keywords:EC Motors, AC Motors, Energy Recovery Ventilation Systems, Indoor Air Quality, Energy Consumption, Advanced Motor Control, Speed Control Performance, Airflow Adjustments, Installation and Maintenance, Reliability, Cost-Effectiveness