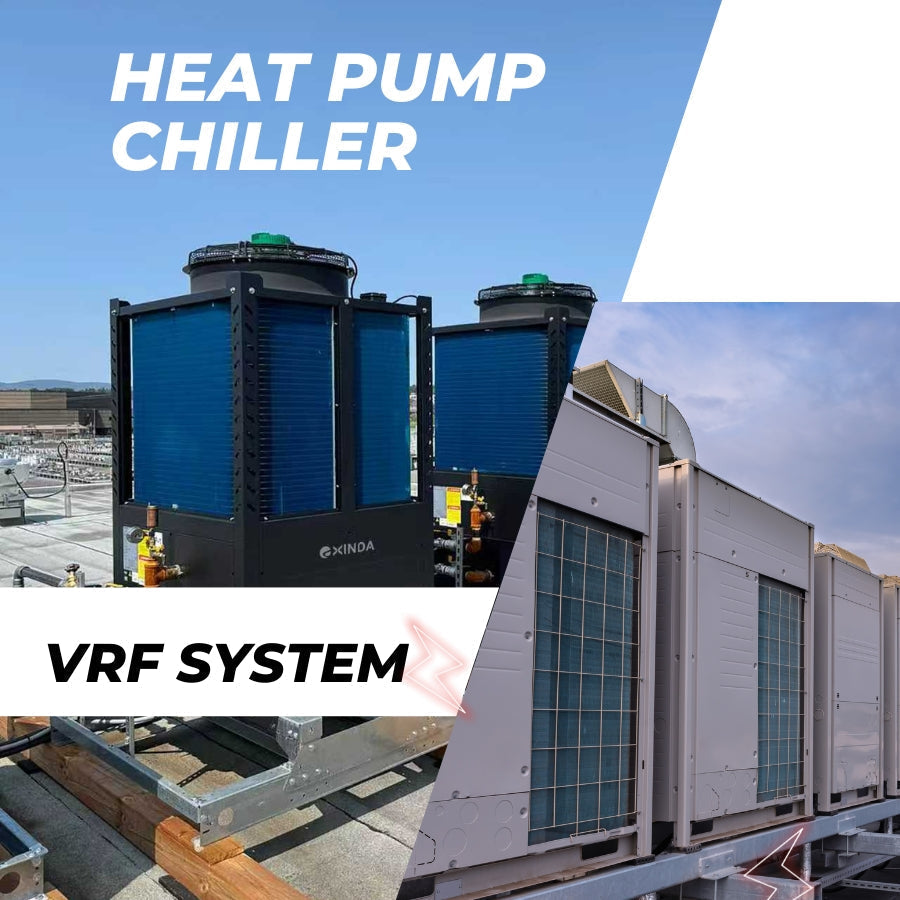

The U.S. and Canadian commercial HVAC markets are entering a new era. With R410A refrigerant being phased out and stricter safety regulations around A2L refrigerants, building owners are facing a major decision: upgrade existing VRV/VRF systems or switch to Air-to-Water (ATW) heat pump systems

For many, ATW is emerging as the smarter long-term choice: safer piping, stability across refrigerant regulations, and lower operational costs.

Why VRV Replacement Is Coming

R410A Phase-Out: All VRV infrastructure using R410A will need full replacement.

Refrigerant Safety Concerns: A2L refrigerants require stricter safety measures; VRV always container large volume of A2L refrigerant, may cuase refrigent leakage problems. water piping avoids these issues.

Next Refrigerant Transition: Hydronic systems are immune to refrigerant phase-outs, making them future-proof. The next frigerant could be A1 transition inlcuding R290 (explosive refrigerant)

Why Air-to-Water Makes Sense

First Cost Within Reason: More affordable than full VRV replacements, especially when leveraging efficient ATW configurations.

Easier Installation: Water piping is easier to install and retrofit than large refrigerant piping.

Long-Term Stability: ATW systems are safe from refrigerant regulations.

Better Efficiency: ATW units with inverter and EVI technology provide high COP and energy efficiency in all seasons.

Fan Coil Options for ATW Retrofits

In commercial and institutional buildings, these indoor units are commonly used:

- Horizontal ducted fan coils

- Ceiling cassette fan coils

- Vertical units in utility areas

- Hi-wall mounted units – growing in interest for hydronic, though more common for VRV/DX today

Quality hydronic fan coils made in Asia — including China — are gaining acceptance, especially when supported by robust service and certification.

Matching VRV Logic with ATW Systems

Many VRV systems support 6–8 indoor units per outdoor condenser. ATW systems can follow similar design logic:Connect multiple indoor fan coils to a single ATW unit

Take advantage of load diversity in different zones (e.g., bedrooms vs. kitchens). This design ensures comfort while avoiding oversizing, much like VRV systems today.

Roadmap for ATW Adoption in the U.S&Canada

- Target buildings already needing VRV replacement (e.g., schools, offices).

- Educate contractors on the safety and installation ease of ATW piping.

- Offer competitive packages (ATW + fan coils) with first-cost advantage.

- Showcase case studies highlighting energy savings and performance.

- Partner with indoor unit suppliers to ensure local support and availability.

How EXINDA Supports ATW OEM for U.S.Canadian Market

EXINDA is not just an manufacturer specializing in high-performance air-to-water (ATW) heat pumps designed for North America.

1. Built for North American Standards

CSA & AHRI compliance-ready

Operates down to -30°C with inverter + EVI

ERP A+++ ratings and low-GWP refrigerants

2. Flexible OEM/ODM Customization

Private-label support for brands/distributors

Custom tonnage from 3–30 tons

Compatible with ducted, cassette, and wall-mounted fan coils

3. High-Quality Manufacturing

ISO-certified production

100% unit testing before shipment

Trusted components: Panasonic/Coperland compressors, SWEP heat exchangers, Carel controls

4. Fast Engineering Response

In-house R&D testong lab for quick North American adaptations

Hydronic system design for VRV-style retrofits

5. Full Technical & Marketing Support

Technical documentation & training for installers

Sales kits, branded brochures, and case studies for partners

Final Thoughts

With the refrigerant phase-out accelerating and safety regulations tightening, switching to hydronic ATW systems is no longer a niche idea – it’s the next logical step. For contractors, designers, and building owners, ATW systems offer reliability, safety, and long-term savings.

Backed by EXINDA’s proven OEM manufacturing strength and North American market knowledge, this transition becomes not only possible – but profitable.